Free six sigma calculator which combines multiple tools into one: To calculate process yield, we use the following formula:

Six Sigma Calculator Alternatives and Similar Software

For instance, consider the following values:

How do you calculate six sigma. And sigma = 3.37, defect % = 3.08, yield = 96.92. Multiply three by the standard deviation, then add the mean. 10, 12, 8, 9, 6.

Learn more at sigma notation. Just remember to always perform mathematical operations on proportions, not on. Sigma is fun to use, and can do many clever things.

That’s because airline safety operates at a level higher than six sigma, while baggage reliability operates at about four sigma. 7 articles of lost mail per hour. Your yield here would be 145,500 minus 250, divided by 145,500.

Yield is the percentage of products or services without defects. 6 rows to calculate yield, subtract the calculated value of defects from the total opportunities, then. Sigma is a measurement of variability, which is defined by the investor words website as the range of possible outcomes of a given situation. add a set of data and divide by the number of values in the set to find the mean.

10, 12, 8, 9, 6. Now, you should judge your yield against the standard baseline (99.99966%) for six sigma success. By plugging in your scores you get the following:

You might also like to read the more advanced topic partial sums. Organizations determine the sigma levels of given processes (one sigma, six sigma, etc.) as a means of comparing the performance of those processes throughout the entire organization as distinct elements. This is the high end of the normal range.

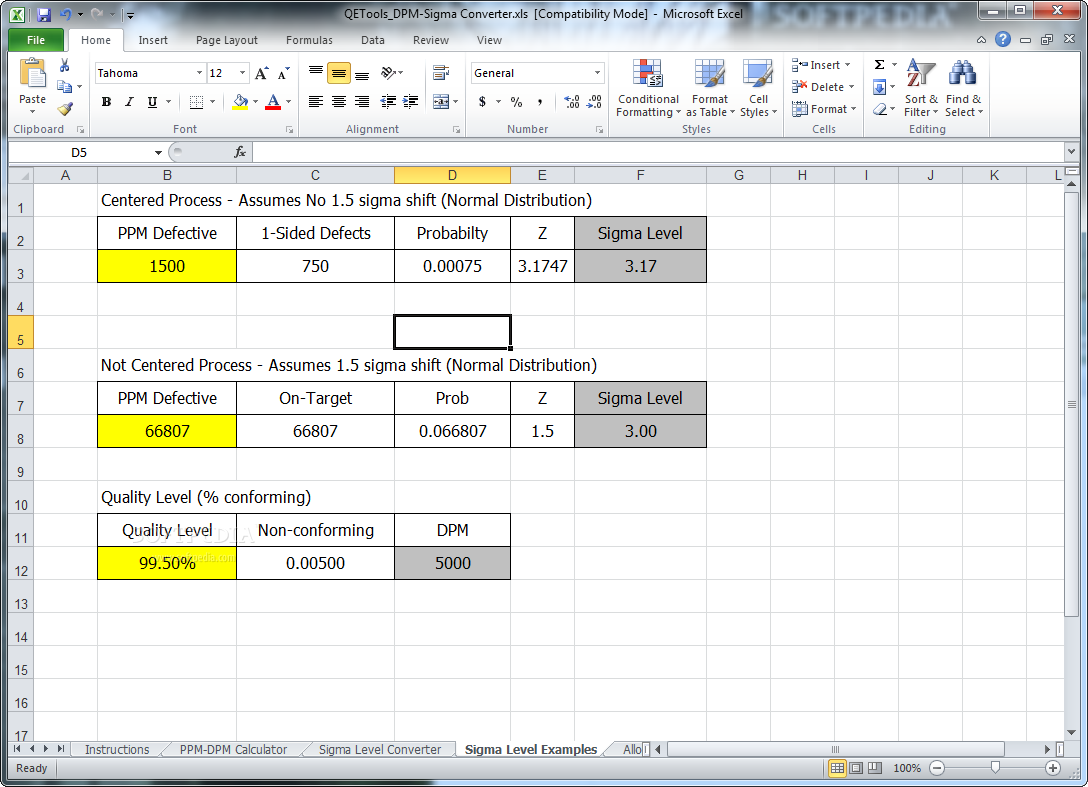

Based on the process sigma table, six sigma rating should have 99.99966% yield. N^2 images/sigma2.js what is sigma? Figure 2.8 illustrates the capability of one sigma through six sigma for the long term when the process is offset by 1.5 sigma.

In practice one can also determine dpmo by dividing total defects by the total opportunities and multiplying the results by a million. First, the number of products you produce. Calculates defects per million units (dpm), percent defects from all.

This symbol (called sigma) means sum up it is used like this: Defect, opportunity, and defect rate. Second, the number of production errors per product.

To check if a bpo company is utilizing a six sigma process, we compute for the three main components: 99% good (3.8 sigma) 99.99966% good (six sigma) 20,000 lost articles of mail per hour. Sigma is a measurement of variability, which is defined by the investor words website as the range of possible outcomes of a given situation. add a set of data and divide by the number of values in the set to find the mean.

In other words, it is the intended result of the metric that we measure. You can calculate the defect rate by dividing the number of defects by the total units that you produce within a period. Number of opportunities for error per unit 3.total number of defects 4.solve for defects per opportunity dpo = ( d )/ ( u *o ) 5.convert dpo to dpmo dpmo = dpo * 1,000,000 6.look up process sigma in.

With numbers this big, it turned out that the four sigma process made 18,710 more errors than the six sigma process. Finally, it's time to find the three sigma above the mean. 31 rows to do the six sigma calculation, you will need to 4 pieces of data:

How to calculate your process’s baseline sigma. Third, the total number of production errors. To find the low end, multiply the standard deviation by three and then subtract the mean.

The process yield is calculated by subtracting the total number of defects from the total number of opportunities, dividing by the total number of opportunities, and finally multiplying the result by 100. Defects occur in the production process when businesses don't effectively manufacture units of a product. Often, voice of the customer is the input for customer specification limits.

In this case, the traditional yield is. One should also note that the calculation of sigma levels for a process data is independent of the data being normally distributed. Before you begin to measure your baseline sigma, you must first collect three sets of data.

To go from percentage back to proportion, divide the percentage by 100. For instance, consider the following values: So, (3x2.56) + 5.45 = 13.13.

Yield (%) = (1 − dpo) × 100. In this example, the hospital would get 99.828 percent. Dpmo calculator, dpm calculator, rty calculator, sigma level calculator.

2 ways to calculate six sigma (for continuous and discrete data) 1.number of units processed 2. Customers set the limit (upper and lower) on the product. Likewise, people ask, how do you calculate sigma?

Specification limits are the targets set for a product or the process by customer or market performance; Unsafe drinking water for almost 15 minutes per day. You can convert from a proportion such as 0.986 to perhaps a more familiar percentage scale by simply multiplying the proportion by 100.

Also, how do you calculate sigma? Six sigma (6 σ) is a set of. Don’t round up the figure, as precision is important here.

Because six sigma focuses on achieving 3.4 errors per million products, this should be your goal. Online sigma calculator for use in process control and quality assurance in industrial applications as well for overall business project management. Just type, and your answer comes up live.

A key factor in determining a process’s sigma level is the defects per million opportunities. Six sigma professionals can measure a process’s dpmo and gauge its level of. Here is a list of common six sigma metrics, with an explanation of each metric: