Tqm refers the control for all transformation processes of an organization to best satisfy customer’s need in the most economical manner. 3) establish root cause (s).

Project Management Total Quality Management, Tools and Techniques for TQM

Seven tools of quality the old seven. the first seven. the basic seven. quality pros have many names for these seven basic tools of quality, first emphasized by kaoru ishikawa, a professor of engineering at tokyo university and the father of quality circles.start your quality journey by mastering these tools, and you'll have a name for them too:.

Tqm process improvement tools. To make sure you are ‘doing the right things, right the first time, every time’, the tqm framework places great emphasis on companies having solid processes in place to reduce errors. The effective use of these tools and techniques requires their application by the people who actually work on the processes, and their commitment to this will only be possible. • this is a cyclical style to be iterated until the process is perfected.

Icor (inputs, outputs, controls and resources) is an internationally accepted process analysis methodology for process mapping. This page describes the tqm methodology or the principles of tqm. Improvement or if it should be introduced onto the market.

Icor (inputs, outputs, controls and resources) is an internationally accepted process analysis methodology for process mapping. Some of the widely applied tqm tools and techniques are: In addition, when implementing tqm, it is beneficial to have an understanding of process mapping and cycle time analysis.

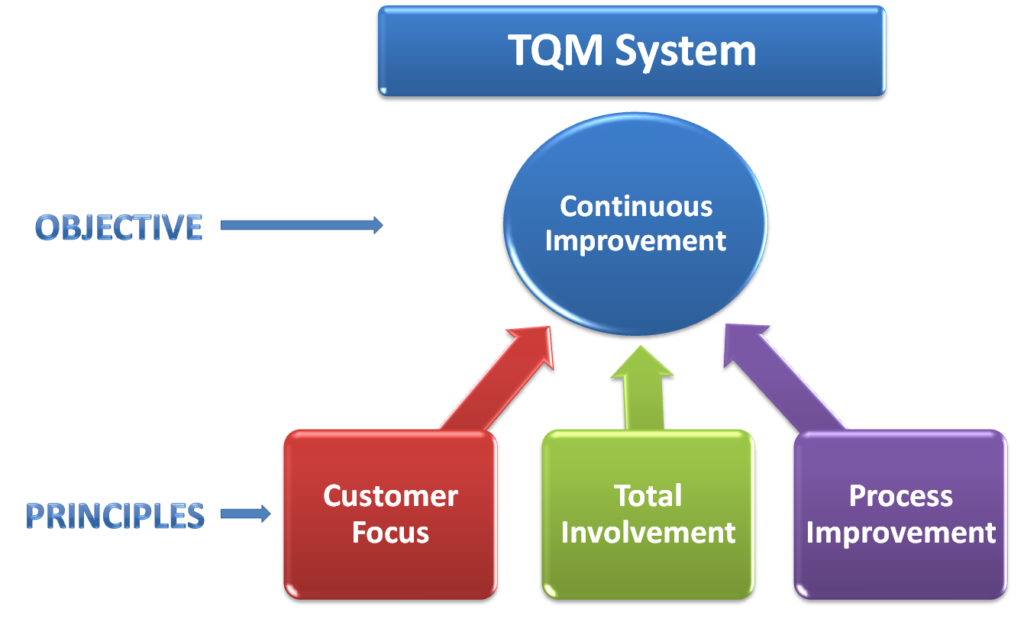

Tqm is a quality management process that looks for continuous improvement in any industrial aspect. Process maps are useful communication tools that help improvement teams understand the process and identify opportunities for improvement. New managerial philosophy and practices that should permeate every aspect of.

History, gurus, tqm and process improvement. With a strong emphasis on organizational change, deming’s principles for total quality management is more accurately titled “deming’s 14 points for the transformation of management,” or simply “14 points for management.”. Continuous improvement utilizing analytical techniques.

Ironically, tqm began in japan based on the quality philosophy of dr. The tqm tools procures significant improvement in. More specifically, tqm encompasses technical competences for the definition of:

Tqm is not a flavor of the month management. That improvement can be defined as an employee’s ability to provide on. Achieve perfection by continuously improving the business and production process the improvement is made by * viewing all work as a process * making all processes.

Understanding processes so that they can be improved by means of a systematic approach requires the knowledge of a simple kit of tools or techniques. • total quality • world class manufacturing (wcm) Edwards doming who is an american.

He first presented these fourteen points in out of the crisis: Quality based organizations should strive to. Tqm tools stands for total quality management instruments, not for one type of organization, but for all kinds of organizations.

They may be called different names, have slightly different approaches, but all have the same fundamental requirements: There are five basic steps in any improvement process. Total quality management is a management approach that focuses on delivering products and services with the highest quality to maximize customer satisfaction and meet regulatory standards.

Having solid processes in place means that the root cause of mistakes can be identified, the repetition of these errors can be prevented, and the quality can be improved,. Every business improvement, quality improvement, or continuous improvement process is part of tqm methodology. In a tqm effort, all members of an organization participate in improving processes, products, services, and the culture in which they work.

It allows processes to be broken down into simple, manageable and more easily It states that all employees including the management need to work towards improving the existing business process, adding productivity and efficiency and interconnectivity across various departments in the organization. It allows processes to be broken down into simple, manageable and more easily understandable units.

The above tqm tools can provide comprehensive methodologies to establishing fact based approaches to continual improvement. All of these tqm tools can be easily created and examined by. Tools & techniques for process improvement.

Create constancy of purpose for improving. Total quality management (tqm) tools total quality management (tqm) tools help organizations to identify, analyze and assess qualitative and. The history of quality management, from mere 'inspection' to total quality management (tqm) and its modern 'branded interpretations such as 'six sigma', has led to the development of essential processes, ideas, theories and tools that are central to organisational development and change which are.

Total quality management (tqm) is a company wide philosophy that focuses on customer satisfaction. Tqm emphasizes continuous improvement through the development of.

TQM TOTAL QUALITY MANAGEMENT TQM Meaning

Benchmarking in TQM With Examples and Benchmarking tools

What is TQM PresentationEZEPresentationEZE

Introduction to TQM. Total Quality Management.PresentationEZE

TQM Program Implementing Total Quality ManagementPresentationEZE